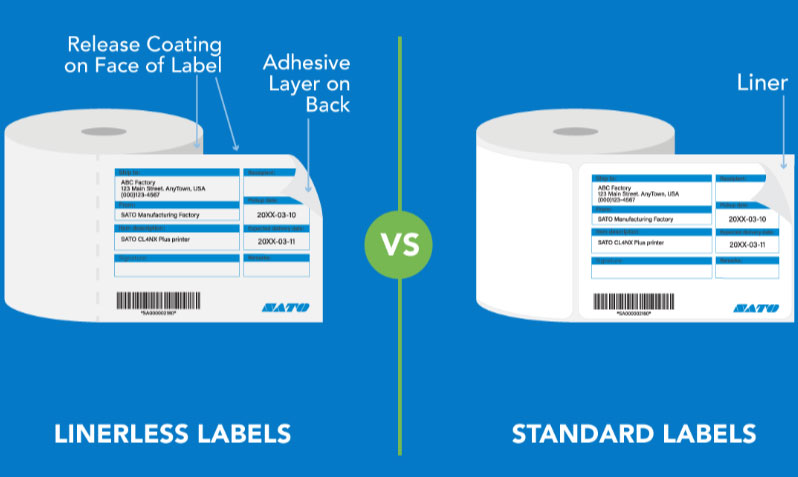

SATO’s linerless labels offer a proactive approach, significantly reducing waste, improving operational efficiency.

Addressing challenges of conventional labels traditional labels present notable operational and environmental challenges: Material waste from liners (20-30% of total label material). Frequent roll changes disrupting workflow.

High costs and complexities associated with liner disposal. Increased environmental footprint.

Learn More About Linerless Labels

Advantages of Linerless Labels

30-40% more

labels per roll

Less storage

space required

Reduction in

transport costs

Lower CO2 emissions

(no incineration of

backing paper)

Reduced downtime

(operator non-

productivity)*

No backing paper

=

No waste

Linerless, Permanent

Main applications in:

- Weigh scale Labels

- Logistics Labels

- Bag Seal/Content Labels

- Product Labels in Food

- Horticulture Labels

- Customised Options

Often overlooked advantage vs PSL – higher efficiency of labelling.

Label separation by cut, perforation or tearing.

Linerless, Removable

Main applications in:

- QSR/ Fast Food

- Logistics Labels

QSR Linerless already highly adopted in North America, Europe is following now.

Removable Logistics Labels for shipment flow control in internal logistics.

Label separation by cut, perforation or tearing.

StripStik™, Markdown

Combines linerless benefits with security: leaves visible tamper marks when removed improperly.

Reduces total cost of ownership—less waste, fewer roll changes, and lower storage/shipping costs.

Boosts operational safety — no liner paper on floors means no slip hazard

Committed to Quality and Sustainability

Explore how SATO ensures the highest standards of quality and environmental responsibility.

Learn more about our certifications and awards that reflect our dedication to excellence in every product and solution.

Discover our Certifications

Contact us