Improve labelling productivity, accuracy and reduce your costs

Discover the beauty of powerful on-board intelligence with Application Enabled Printing (AEP). Simplify the labelling process for your customers with the ability to customise printer operations, significantly reducing costs and improving operational efficiency.

Versions available from SATO:

AEP

AEP

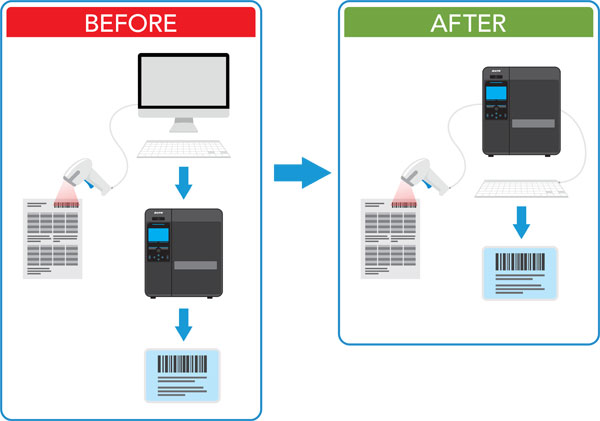

Allows for tailor-made labelling applications including PC-less printing, direct connection of peripherals such as keyboards, scanners and scales for data input

Web AEP

Web AEP

Expands the powerful AEP platform to system integrators who prefer using common languages like JavaScript, HTML5 and CSS for applications development

AEP

| What is AEP? | Customer Benefits |

PC-less - Eliminates the need for separate printers and PCs, with no third-party software for OS and middleware, no licenses required and easier update roll out |

Perfect fit - Ideal for areas where space is minimal, or the environment is unsuitable for a PC |

Peripheral device connection - Printer can process info internally and link to devices such as scanners, weighing scales, thermometers and PLC |

Reduce total cost of ownership - Reduces business downtime and decreases system maintenance with less recurring costs |

Onboard intelligence - Decisions are made by printer and not by unqualified staff |

Improves the labelling process - Easy and intuitive labelling process that improves efficiency and productivity, while minimising the risk for human errors |

Cloud enablement - Connect the printer directly to IT and cloud systems |

Direct connectivity to IT and cloud systems - Reduces system complexity meaning less things can go wrong and makes troubleshooting easier |

Suitable for

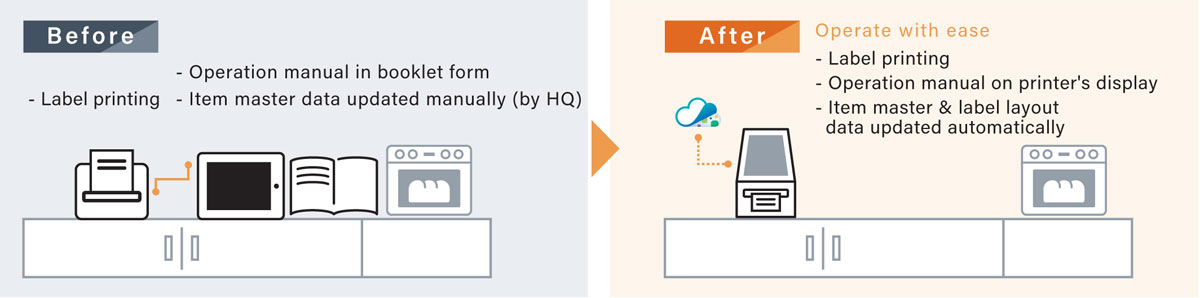

STRESS-FREE PRINTER OPERATION Intuitive Printer Display Solution

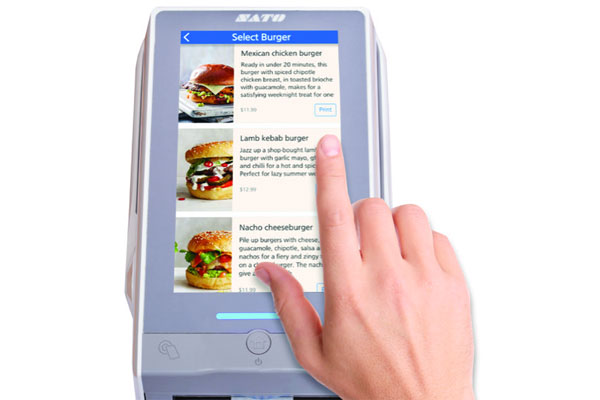

Streamline and enhance printer operations by configuring the printer to display only the information that is relevant.

Typical Customer AEP Case Studies

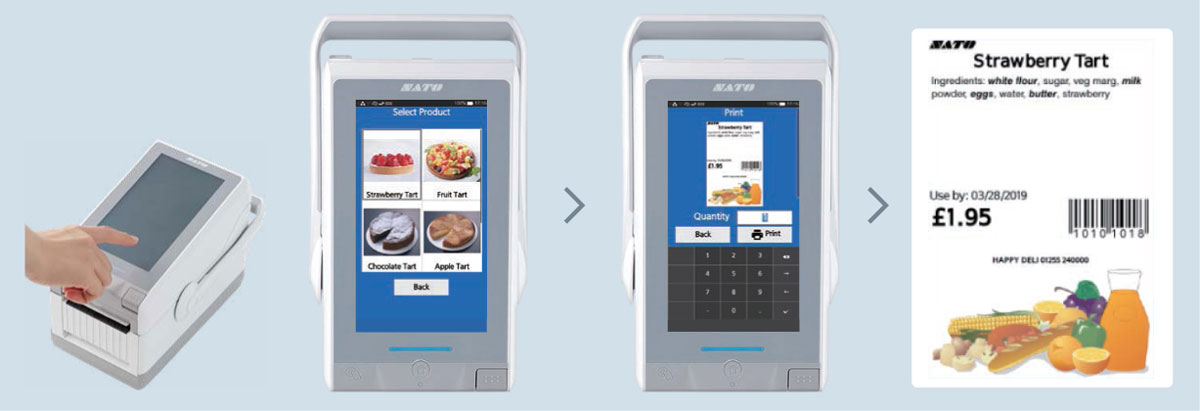

Food Retail - Leading Bakery Chain

Customer Challenges:

- Equipment and operations were too complex to manage as different brand hardware and systems were used.

- Lack of space as stores did not have adequate room to store all equipment.

- Headquarters updated label data for all stores via a manual process, which is not only time consuming but is prone to human error.

The SATO Solution: The FX3-LX with AEP

The FX3-LX with AEP offers a complete solution for ingredient labeling of our fresh bread products. Thanks to its ease of use, the large 7-inch full colour touchscreen provides categories that are quick to navigate, helping employees search and locate products at speed. The printers are connected to SATO App Storage, a cloud-based service for managing label data and design templates centrally. The customer's headquarters can now update data across its chain stores instantly, while stores can print labels more easily with minimal equipment.

Customer Value:

- Compact and portable size means the FX3-LX can be placed anywhere or carried by the user.

- Label data and designs could be centrally managed, enabling operators to save 50% of their time, which could then be dedicated to customer service.

- Staff can easily adapt to the new and intuitive system through smartphone and tablet familiarity, making it simple to use with minimal training required.

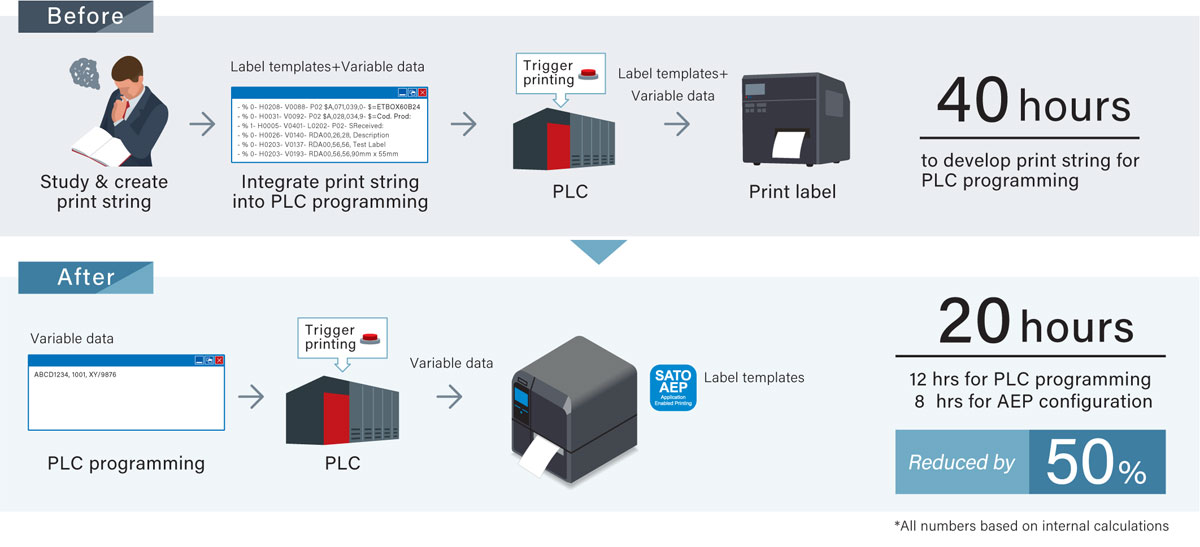

Automotive - Multinational manufacturer of automobiles

Customer Challenges:

- PLC engineers take time to learn the printer programming languages required to integrate label printing with their system, resulting in long lead times.

- Limitations in flexibility means that any modifications or additions to label templates that are required results in an engineer needing to reprogram the PLC with new printer commands.

- Low productivity due to a need to maintain printer programming code for different label formats.

The SATO Solution: The CT4-LX, CL4NX Plus or CL6NX Plus with AEP

AEP simplifies label printing from a PLC. The label templates can be saved in the printer, so that only variable data needs to be sent from the PLC (as comma-separated text files) for label printing.

Customer Value:

- Improved flexibility and speed of deployment with label template data handled autonomously by AEP, meaning PLC engineers are no longer required to program the PLC for label printing.

- Reduced costs as engineers spend less time on PLC programming, saving up to 50% in production hours alone.

- Increased productivity as AEP makes it possible for the same printing application to be easily implemented at any manufacturing plant.

Manufacturing - Warehouse & Logistics Operations

Customer Challenges:

- Workplace is unsuitable for a PC due to inadequate space or inappropriate environment.

- Labels are printed in batches and taken to the manufacturing site, increasing the risk of attaching labels to incorrect items.

- High cost of asset management to maintain PCs and other IT resources.

The SATO Solution: The CT4-LX, CL4NX Plus or CL6NX Plus with AEP

With AEP, lot labels can be easily printed on the spot without a PC. The label lay-outs are stored in the printer and data input is completed on the onscreen keyboard or with a full-size keyboard, numeric keypad or scanner which are connected directly to the printer.

Customer Value:

- No PC required at the workplace

- Reduced total cost of ownership with no need for hardware, software licensing or additional maintenance costs.

- Labels can be printed at the manufacturing site whenever they are required, eliminating the need for batch printing.

Healthcare

Customer challenges

Printing patient wristbands are printed from a PC which are costly and take up space. Those are only available at the patient registration area or at specific nurse stations and require IT clearance before access.

SATO’s solution: The CT4-LX with AEP

Easily print & encode RFID wristbands without PC at patient admission by scanning a 2D code with patient information for example from a smartphone app. When an existing standard barcoded or RFID wristband is scanned, a new wristband for in-patient or for patient who has for example undergone an MRI procedure can be reissued by simply connecting to a CT4-LX located in the ward.

Customer value

- Standard barcoded or RFID patient wristbands are accurately printed without PC

- On-site reissue of the wristband greatly reduces the risk of patient misidentification

- PC-less operation saves space and cost of devices, licenses and maintenance

- Easy and intuitive printing process makes it simple to use with minimal training required

AEP Supported SATO Printers

Slide right to see full table as required

For more information on our AEP solution, contact your nearest SATO representative today.

Web AEP

| What is Web AEP? | System Integrator’s Benefits |

| Everything that AEP can do, plus more! - With all the capabilities of AEP, Web AEP gives you extra flexibility wherever you need it most, making complex builds that much easier | Seamless integration into existing cloud based applications |

| Faster builds with JavaScript, HTML5 and CSS - The GUI is developed as a web application with JavaScript, HTML5 and CSS with the preferred JavaScript frontend framework like Vie.js, Angular, Jquery or React | Intuitive programming by industry web standards |

| Existing web apps - Convert existing web apps to run on the FX3-LX or CT4-LX | Unique solution for the Auto-ID industry to integrate printers with cloud-based systems and without third party software |

| Local or cloud web applications - Run local web applications on the printer or connect the printer as a client to web applications running in the cloud | Provide a durable and stable operation to the end-user |

| Minimal training requirements - Short learning curve since you only need to learn how to run web applications on the FX3-LX and CT4-LX | Minimal training requirements & cost savings |

Suitable for

Typical Customer Web AEP Case Studies

Case Study - Local Web Application

With Web AEP, you can create Single Page web Applications (SPA) with JavaScript, HTML5 and CSS - popular to ISVs. Partner benefits include the ability to:

- Provide a unique solution to your customer with a multi-functional, all-in-one device

- Develop applications with common web technologies

- Convert your existing web apps and assets to run on the FX3-LX or CT4-LX

- Develop more flexible and creative screen designs than screens created with AEP Works 3

Case Study - Cloud Applications

With Web AEP, you can easily run an app from the cloud on the printer. Partner benefits include the ability to:

- Provide a unique solution to your customer with a multi-functional, all-in-one device

- Reliably run business critical applications with multiple printer due to the powerful server hardware and software

- Deliver business logic enhancements and bug fixes with a single deploy of the server application, so there’s no need to upgrade each printer

- Connect easily to all types of databases including third party API and integrate with existing web applications

- Enable faster development for the most complex solutions in JavaScript, HTML5, CSS, ASP.NET, PHP, C#, Blazor and more

- Easily connect to your existing cloud application with minimum modification required

Web AEP Supported SATO Printers

Slide right to see full table as required

For more information on our Web AEP solution, contact your nearest SATO representative today.