How Frankie & Benny’s uses SATO Delivery Cloud to Streamline their Food Delivery

18/10/24

The coronavirus pandemic transformed the way people work around the world, but it also changed other lifestyle habits. While the hospitality industry was hit hard by closures, food deliveries surged — increasing 24 percent in France compared to pre-pandemic times according to Statista, and more than doubling in market size in the US, according to McKinsey & Company. In the UK, food delivery is thought to be a £14.4 billion market in the UK in 2023 with further growth expected until 2027. But there were substantial growing pains to getting here.

Table(t) d'hôte

During peak times, restaurants struggled to keep up with labelling compliance with delivery and take away orders. Frankie & Benny’s, a chain of Italian-American restaurants in the United Kingdom which offers online delivery, was dealing with multiple delivery companies to receive delivery orders. All deliveries received a branded label for the order number and order content, but these were written out by hand — a tedious and mistake-prone process.

Getting orders out the door accurately and on time is critical not only for customer satisfaction but for a restaurant or takeaway’s ranking in search results from delivery partners. If you’re using a delivery service app and searching for Chinese food in London’s East End, for instance, it will rank the speediest eateries higher than slower ones.

“The main concern was time,” says Emma Male, Food Safety Team, SATO UK. “When an order came through, they would have to sit down and handwrite out the label, spelling out the order contents and order number to ensure the incoming and outgoing orders matched. It was not efficient.”

Handwritten label formats were a headache

Enter the SATO Delivery Cloud

Richard Cross, sales manager at SATO UK, learned about the problem while visiting customers during the peak of the pandemic. He and his colleagues found food workers struggling with delivery platforms amid pandemic-fuelled demand.

“Even the simplest of operations, you want to see the environment, and we go along with the operations guys,” says Cross. “You’re in that space and suddenly someone will go, ‘Oh, you can’t fix this problem for me, can you?’ That was the catalyst. It just opens your eyes a bit. You realize other companies will have the same problem.”

SATO’s response? Jump right in and engineer a solution that consolidates all order information from various delivery partners and prints it out when needed — only one printer required. That’s what the SATO Delivery Cloud does. Currently available in the UK and Ireland, Delivery Cloud works with the cloud-connected FX3-LX label printer designed for the food, manufacturing, and logistics sectors. Delivery Cloud has been making an important difference by streamlining operations at food service providers, boosting productivity and sustainability.

The many benefits of automating food delivery labelling

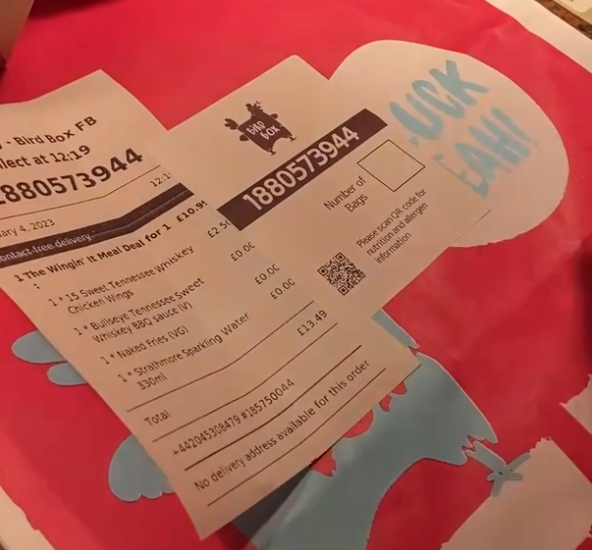

Example of a printed delivery label

SATO software developers worked with several food delivery software-as-a-service (SaaS) vendors and restaurant managers. They dealt with complex menus, customisable orders and the fact that the SaaS provider data was not in the format required for label printing by end users. There were many complexities with the various menus. “Does a meal include a drink and fries?” for example. When info was not received from one delivery company’s system, SATO had to break down what that meant. Systems cannot comprehend some details which are obvious to humans. Terms like “meal deal” does not compute without data modifiers.

Also, there was the complexity behind which product needs labels. But, there was also a gray zone in terms of maintaining order accuracy. For example, would two cans of Coke require two labels? Drinks, food items, even cutlery now are labelled.

With guidance from the sales team, SATO’s developers overcame these challenges and created a solution for real-time order queuing from scratch. Regardless of when the order is placed, kitchen staff prepare them so they are hot and ready when the delivery carrier arrives. Modifiers like no pickles, extra cheese etc. were set to be picked up by the printer and the label would reflect that.

In addition to saving time, SATO’s solution saved both money and space while enhancing efficiency.

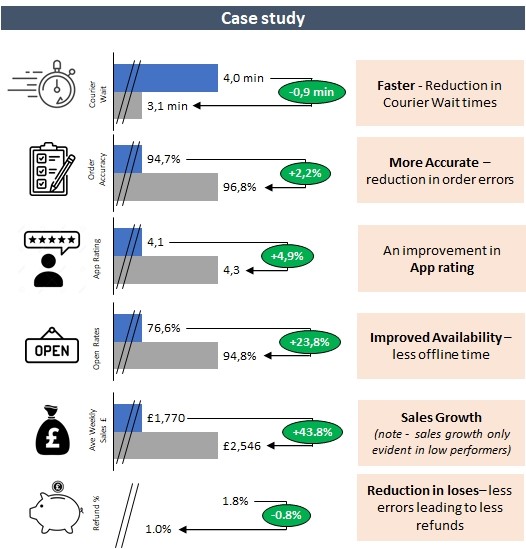

“The SATO label printer has been implemented as a delivery solution across our leisure estate. It works by removing the requirement to handwrite dish labels for orders coming from our delivery partners (Deliveroo, Uber & Just Eat),” says Frankie & Benny’s Manager Andrew Smith. “This has been a huge step forward in operations, allowing a clear and consistent procedure for all locations, reducing the complexity that comes with operating multiple brands, and freeing up employee hours for other tasks. We have seen an immediate improvement in some of our KPIs, especially time to produce and hand over an order to a courier, and the accuracy of ensuring all items that have been ordered are packaged.”

We start where you are

The SATO Delivery Cloud is convincing customers that investing in high-quality cloud-connected label printers like the FX3-LX makes better business sense than “throwaway” alternatives with lower upfront cost but a much shorter product lifespan. The team now plans to roll out the solution to more than 140 affiliated restaurants. It’s been a success that may translate to other users and industries, but it took quick thinking and bold steps by the SATO UK team.

“It was really hard because we had to sell them something that we didn’t have,” says Male. “We had a concept with nothing to show, but we believed we could create something. So, we had to come up with a solution on the fly. This is where SATO worked really well in terms of our developer and client-liaison people. We needed the customer to invest in us and believe in us.”

This project is an example of SATO’s strength in action. Being at the customer site, understanding their workflow and the data input and output points was key to providing attentive support and responding flexibly. Attentiveness to the on-site requirements made it a success.

“I’m always wanting to be in the thick of it, trying to innovate and help my team develop new projects, trying to do in the front rather than managing from the back,” says Richard Cross. “I’m always wanting to be involved in these types of customer problems and innovations and coordinate with the tech team to get the flow and the scope of work right.”

SATO aims to expand the delivery cloud to other regions and store formats, for example convenience stores or gas stations. Any industries that do "click and collect" style sales with pre-boxed foods and quick turnarounds can see benefits with such a solution. We also hope to integrate it with other POS providers to increase its value.

SATO Delivery Cloud overview

SATO Delivery Cloud is an all-in-one label printing application for restaurant delivery and take away orders. It consists of the FX3-LX antibacterial printer and a cloud application to consolidate food delivery orders instantly. The application improves visibility, flexibility, and efficiency across all order channels from one single system, no matter the delivery company. The app integrates with multiple delivery platforms' websites, ensuring instant two-way communication for order updates. Users can consolidate order streams displaying store name, order number, delivery company and products ordered to reduce the risk of wrong orders being delivered or orders missing items.

Emma Male

New Business Development (HoReCa), SATO UK Ltd.

Emma Male has dedicated nearly two decades of her career to SATO UK Ltd. A valuable team member specialising in label solutions, she has established herself as an expert in the HoReCa (hotel, restaurant, and catering) sector. Emma's wealth of experience and in-depth industry knowledge contribute to SATO’s success in catering to the specific needs of the hospitality and food service industry.

Latest News

All News

10/02/26

SATO Europe appoints Armelle Jaclot as European Marketing Director

10 February 2026 – Heidelberg, Germany – SATO Europe...

02/02/26

SATO strengthens its European manufacturing capabilities as Polish site achieves...

2nd February 2026 – Heidelberg, Germany ...